You’ve probably heard of plastic free straws, but what about plastic free oyster reefs?

Oyster larvae (juvenile, free-floating oysters) require a solid substrate, like hard oyster shells, to settle on so they can grow into adult oysters. So why don’t we just throw out a pile of loose oyster shells? Isn’t that enough? Not quite. Dead oyster shells cannot cement together like living oysters can and they are more at risk of sinking into soft mud and sediments and being buried. Wave energy and storms can disperse the shells and the greatest success is seen when shells are held together. Historically, oyster shells were consolidated using plastic mesh bags that prevent the shells from floating away while still allowing for uninterrupted water exchange.

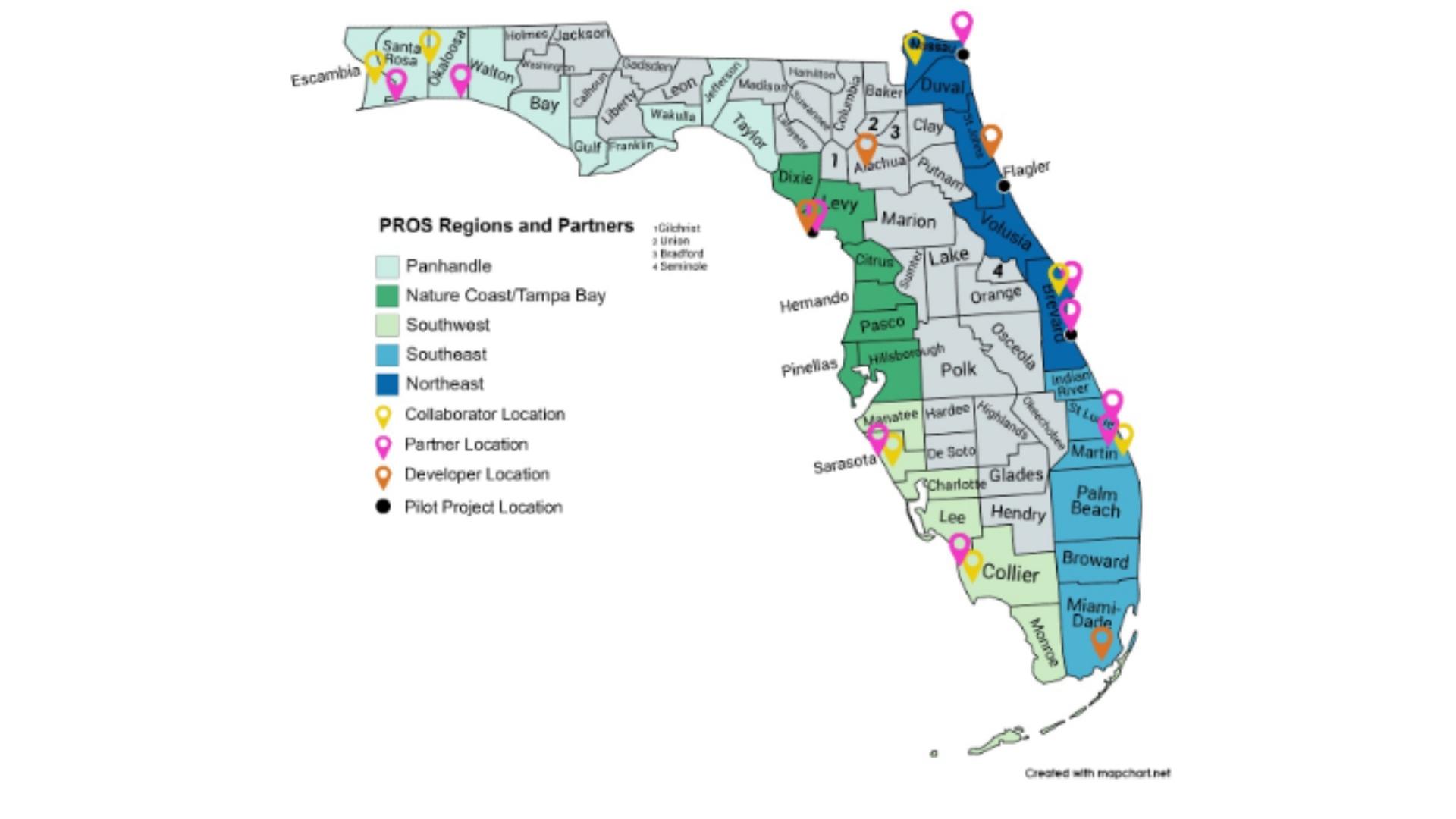

There is growing concern over the degradation of these plastics over time and the restoration community is exploring plastic-free alternatives. An exciting statewide effort is underway in Florida to implement living shoreline demonstration projects using a newly developed plastic-free design called reef prisms. The network of partners, named the Plastic-free Restoration of Oyster Shorelines Community of Practice (PROS CoP), is holding regional workshops across Florida to train partners to build the prisms, collaborating on permitting efforts, and providing monitoring protocols.

PROS project leads Dr. Savanna Barry (Florida Sea Grant) and Dr. Mark Clark (UF IFAS Extension) visited Pensacola to host a prism building training with the GulfCorps OysterCorps in December. The EscaRosa OysterCorps is a branch of the GulfCorps Program that was funded with support from PPBEP’s Community Grant Program. The program provides short-term employment for local young adults, including veterans and those from underserved communities, as well as skills training and experience in jobs supporting local workforce development in the growing habitat restoration field.

Estuary Program staff arrived on site to a flurry of activity; a bucket brigade of OysterCorps members was unloading concrete bags, setting up saw horse work benches, and unloading prism molds. There was excitement (and cement dust) in the air as concrete was mixed (Cement-All and water, or pure Calcium Sulfoaluminate (CSA) cement, sand, and water) and prepared to build prisms. Pre-measured and cut jute (durable, natural plant fiber) mats were quickly folded into the concrete-mix slurry before it hardened. Once the jute fibers were soaked in the mixture they were carefully stretched out across the worktable.

Why Jute? The jute fibers create a form with a rough outer layer that still allows water to travel through the form. These openings are critical to maintain water exchange for oysters and help disperse wave energy.

The PROS team has a lot of experience experimenting with these materials and at this point they have the prism building process down to a science. The project leads provided pre-constructed wooden prism forms and shared several tips and tricks with OysterCorps members. While the jute fiber was still wet, a wooden prism mold wrapped in a sleeve for easy removal, was set onto the jute mat. GulfCorps members wrapped the jute mat around the mold making sure to keep that mat taut as they wrapped it. No material went to waste, any excess concrete mixture left behind on the table was squeegeed and collected. The extra concrete mixture was then added at the final seam to secure the jute matt in place.

Once completed, the assembled prisms were carefully moved to dry. At the end of the workshop, the first prisms that were constructed were already dry! The molds were collapsed and removed, and the oyster prisms were set aside for future deployment.

The oyster prisms that are being deployed across the state will be monitored to evaluate the success of this reef material. If the prisms are successful, expect to see more of these reefs soon!